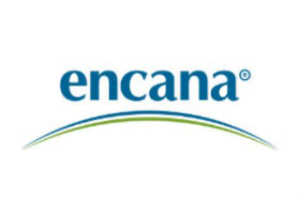

GTI is leading a high-profile program on Hydraulic Fracturing Test Sites (HFTS) in the Permian Basin, bringing together government and industry to improve recovery, continue enhancing environmentally responsible methods of optimizing production, and lowering development costs in the Midland and Delaware Basins.

GTI is leading a high-profile program on Hydraulic Fracturing Test Sites (HFTS) in the Permian Basin, bringing together government and industry to improve recovery, continue enhancing environmentally responsible methods of optimizing production, and lowering development costs in the Midland and Delaware Basins.

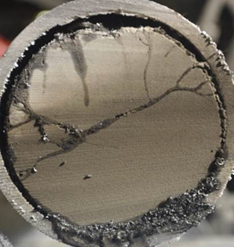

The Hydraulic Fracturing Test Sites (HFTS) are field-based research experiments supported with funding from the U.S. Department of Energy National Energy Technology Laboratory (DOE-NETL) and a consortium of industry sponsors that involve comprehensive reservoir characterization and hydraulic fracturing diagnostics for multiple horizontal well development projects. A unique feature of these programs are the drilling of a post-stimulation core well through the stimulated rock volume to gain direct evidence of fracture growth patterns.

These multiple HFTS efforts will help to advance technology, optimize well spacing, improve the design and execution of fracture treatments, and mitigate environmental impacts of shale development operations. Establishing a broader understanding of hydraulic fracturing will enable efficient and cost-effective resource production and give producers a better understanding of how to reduce water volume and energy input.

HFTS2–Delaware Field Test Site

In January 2018, GTI was awarded funding from the U.S. Department of Energy National Energy Technology Laboratory (DOE-NETL) for cost-shared research and development of hydraulic fracturing efficiency. The new HFTS2–Delaware field test site is located in Loving County, Texas, and features different depth, pressures, and permeability than HFTS1–Midland site, as well as a thicker section of stacked resource. Each HFTS location requires specific techniques for optimal production based on local geologic complexity.

Occidental Petroleum is the operator of the Delaware Basin site, where multiple experiments to evaluate well completion, optimize design, and quantify environmental impact of hydraulic fracturing are being carried out. To date, reservoir characterization has been performed and all production wells have been drilled and completed. A slant well has been cored through the stimulated rock volume to directly measure created fracture patterns, and the well has been instrumented with an array of pressure and temperature gauges.

GTI is utilizing the JewelSuite™ software courtesy of Baker Hughes to organize and perform its analysis of the sub-surface data.

HFTS1–Midland Field Test Site

HFTS1–Midland, also supported by DOE-NETL, along with co-funding from operators and service companies. Laredo Petroleum, Inc. hosted the test site and provided critical geological and reservoir data from many wells in the area.

In September 2015, 400+ fracture stages were completed in 11 Laredo wells in the Wolfcamp formation in the Midland portion of the Permian Basin. A first-of-a-kind through-fracture core sample was produced that documents the physical properties of hydraulic fractures. Along with comprehensive data, it provided insights on how induced underground fractures spread, which is being used to assess the performance of individual fracture stages. It is the most meaningful data set to date for unconventional oil and gas production, providing ground truth evidence paramount to understanding hydraulic fracture growth behavior, validating and developing models, and assessing how predictive analytics can improve the process.

Air and groundwater quality evaluations indicate the HFTS1 well pads had minimal impact on local air emissions concentrations, and analysis of water quality did not find any evidence of natural gas or produced water migration to the groundwater aquifer. Additional water treatment technology evaluations are planned at the site.

Data from the HFTS1 site is now being made available for public use through the NETL's Energy Data eXchange. Similar to HFTS2, GTI is utilizing the JewelSuite™ software courtesy of Baker Hughes to organize and perform analysis of the sub-surface data.

Midland Field Test Site

HFTS1–Midland Partners

Based on industry interest, Phase 2 has been added to HFTS1–Midland, with a focus on enhanced oil recovery (EOR). The effort will explore injection of natural gas into a well to pressure the formation up again and potentially recover another 2–4% of the oil in place. This increased recovery would reduce the number of wells that need to be drilled, resulting in a smaller environmental footprint.

Learn More

Contact the energy experts today